|

Mitutoyo launches the first lineup of its unique probe systems developed with Mitutoyo's own technologies. |

|

In order to provide its users with a full line of CMM probe systems as a total solution to answer their measuring needs, Mitutoyo Corporation has been vigorously pursuing the development of new, unique probe systems with a variety of characteristics. This pursuit has been finally fulfilled; the new line of probe systems, successfully developed and merchandised, will be shipped to all the global markets starting in mid-November of this year. |

|

[Development of the "CMM probe system"] |

In the past, Mitutoyo's coordinate measuring machines used the probe systems manufactured by Renishaw, England, with the few exceptions to this being Mitutoyo's use of its own scanning and vision measurement probes. In order to improve the performance of its CMMs, however, Mitutoyo decided to develop its own probe systems. Hence, it has been engaged in developing various technologies and products for that purpose, as shown below:

The following five probe systems will be merchandised and delivered in the first launch of a series of Mitutoyo probe systems

Our plan for the future is to develop two groups of CMM probe systems: one that can coexist with and the other that excludes Renishaw probes. A total of 700 sets (all five models combined) per year are expected to be sold (domestic and overseas sales combined). |

||||||||||||||||||||||||||||||||

|

[FEATURES & SPECIFICATIONS] |

|

MTP2000 |

|

1. |

A touch trigger probe that allows measurements with ultra-high accuracy. Ideal for measuring precision parts, including metal moulds, etc., which require high-accuracy measurements.

|

||||

|

2. |

Equipped with the automatic probe changing system

|

|

||||||||||||||||||||||||||||

|

MPP-100 |

|

1. |

A scanning probe that allows high-speed measurements. The MPP-100 allows high-speed evaluations of contour errors that occur in measurements of complex free curves.

|

||||

|

2. |

Supports a long stylus

|

||||

|

3. |

Stylus changing system

|

|

|

MPP-300 |

|

1. |

The MPP-300 is a scanning probe for measurements with ultra-high accuracy. It allows high-accuracy evaluations of contour errors that occur in measurements of complex free-forms.

|

||||

|

2. |

The MPP-300 supports a long stylus

|

||||

|

3. |

Stylus changing system

|

|

|

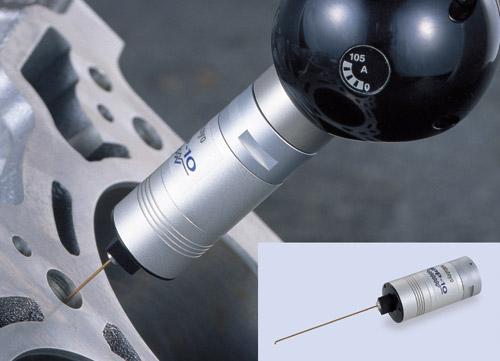

MPP-10 |

|

1) |

The MPP-10 is a probe for use with a coordinate measuring machine, and is designed to measure the effective depth of a screw. |

|

2) |

The MPP-10 allows CMM to measure the effective depth of a screw instead of using an existing dedicated measuring machine with a screw gage. |

|

3) |

Single CMM equipped with an MPP-10 can perform both general coordinate measurements and measurements of the effective depths of screws. |

|

4) |

The patent-pending sensing system that employs an elastic hinge and a rain gage allows high-speed measurements of effective screw depths in constant volumes. |

|

5) |

The automatic probe changing system of the MPP-10 allows interchangeable use of other touch signal probes. |

|

|||||||||||||||||||

|

* |

This product was developed in cooperation with the Graduate School at Hiroshima University, under the direction of Professor Makoto Kaneko, who specializes in artificial complex systems engineering. |

|

QVP |

|

1. |

By installing the QVP vision measuring system in a CMM, miniscule workpieces can be measured that cannot be measured with a CMM alone. |

||||||||||

< CMM with the QVP vision measuring system allows the following: >

|

|||||||||||

|

1. |

The QVP system allows high-speed, high-accuracy non-contact vision measurements by a CMM. |

|

[SPECIFICATIONS OF QVP VISION MEASUREMENT PROBE] |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MPP-300,MPP-100

MPP-10 |

|

November 8, 2001 |

|

|

|

[ Close ] |